Railway Components

Engineering Reliability on Every Track: The Pulse of High-Performance Railway Components.

Engineered for Reliability

Built for Rail Networks

In the demanding world of railway engineering, every component must withstand intense loads, weather variations, and continuous operation. Vaani Industries specializes in precision railway parts using advanced manufacturing and rigorous quality controls, enabling safe transit, innovation, and infrastructure excellence. Our products ensure high strength, durability, and trouble-free performance under extreme railway conditions.

Beyond mere functionality, these precision-engineered parts serve as a foundation for broader infrastructure excellence and technological innovation. By prioritizing tight tolerances and high-performance metallurgy, Vaani Industries facilitates safer transit and more reliable rolling stock.

Railway Components Description

We present a detailed breakdown of the system’s parts, outlining their individual functions and purposes.

Hand Brake Set for LHB Power Car Coach

Hand Brake Set for LHB Power Car Coach provides manual parking braking in high-speed LHB power cars via flex-ball cables and diagonal calipers. It uses a hand brake wheel, roller lever valve, and air reservoir to secure wheels 1 and 7 on slopes.

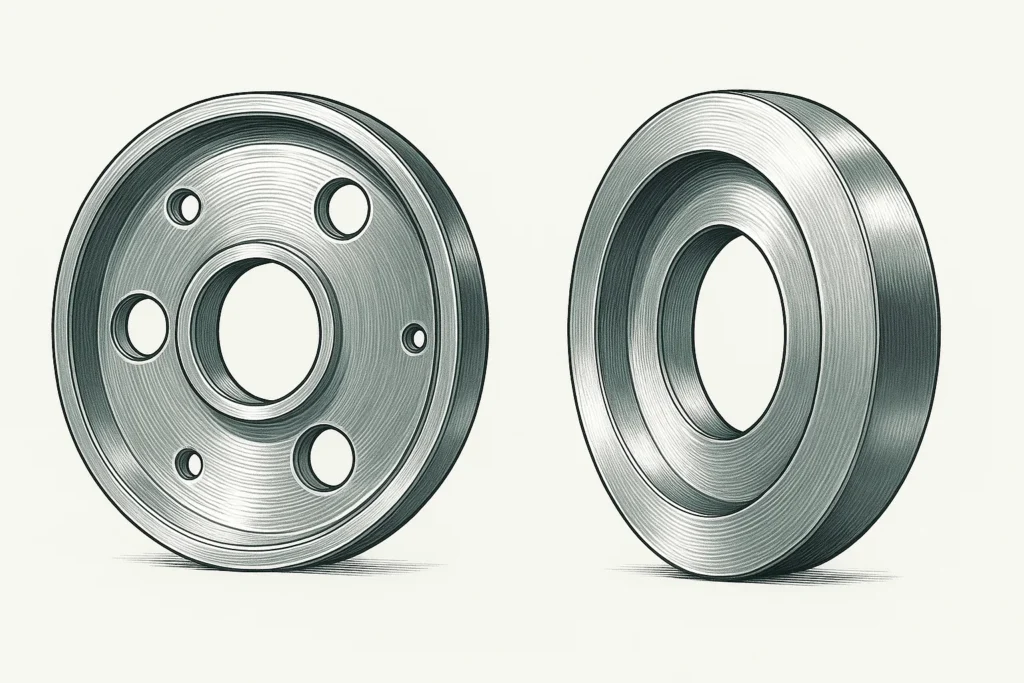

Centering Discs

Centering Discs in railway components align and stabilize bogie bolsters or suspension elements, ensuring even load distribution across axles during train motion. They facilitate smooth rotation at the center pivot, absorb shocks, and maintain precise positioning between coach body and bogie frame for enhanced stability on curves and straights.

Stiffer Cam Shaft

Stiffer Cam Shaft in railway components enhances rigidity in diesel locomotive engines, minimizing torsional flex and vibration for precise valve timing and fuel injection under high loads. It drives inlet/exhaust valves and fuel pumps via robust lobes, ensuring reliable performance in ALCO locomotives during extended high-speed operations. This design boosts engine efficiency, reduces wear, and supports smoother power delivery in freight and passenger services.

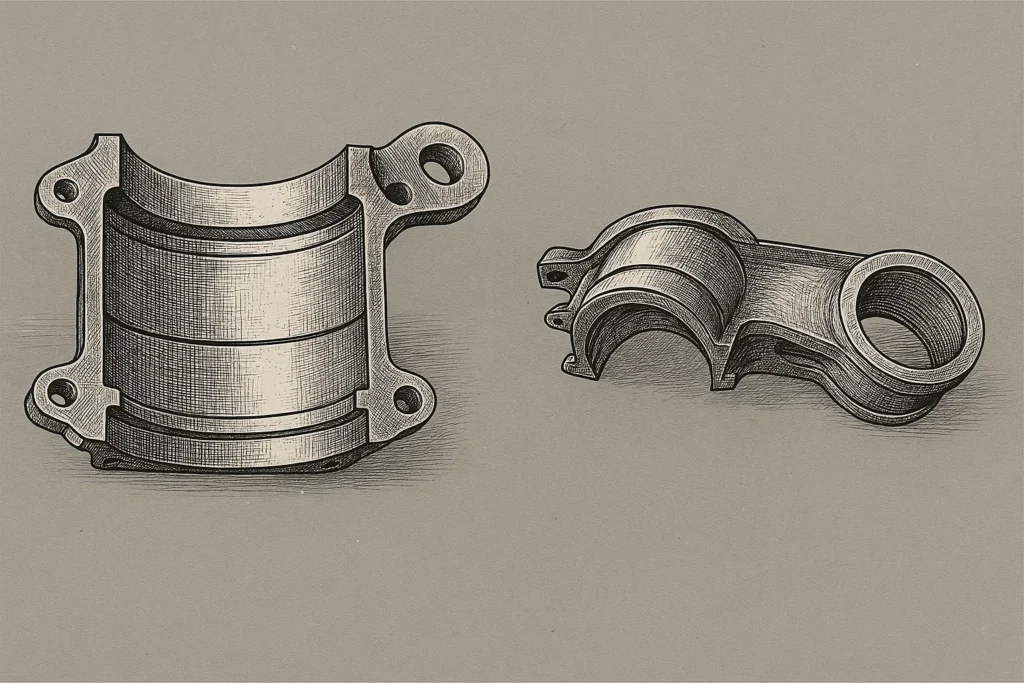

Control Arm

Control Arm in railway components links the axle box to the bogie frame in LHB coaches via elastic rubber joints, transmitting traction, braking forces, and ensuring axle centering. It enables flexible vertical movement with primary springs, absorbs track irregularities, and maintains stability during curves and high speeds.

Set of Pins and Bushes

Set of Pins and Bushes in railway components forms durable pivot joints in bogies, brake rigging, and suspension systems, enabling smooth rotation while reducing friction and wear. Pins act as hardened axles, paired with bushes for load-bearing alignment in couplers, levers, and control arms under high dynamic stresses. This assembly ensures reliable motion transmission, vibration damping, and extended service life in coaches and locomotives.

Brake Gear Arrangement for WAG-9/WAP-7 locomotive

Brake Gear Arrangement for WAG-9/WAP-7 locomotives features TBU/PBU assemblies with brake cylinders, levers, and rigging that transmit 260 kN (WAG-9) or 182 kN (WAP-7) braking force via bogie frames. It integrates regenerative, automatic train, direct loco, parking, and anti-spin brakes for heavy freight (WAG-9) or high-speed passenger (WAP-7) operations. This setup ensures efficient force distribution, minimal hanger failures, and reliable stopping under dynamic loads.

Brake Head

Brake Head in railway components houses the brake shoe and presses it against the wheel or disc during braking, ensuring effective friction for stopping power. It mounts on brake beams or rigging in bogies, designed for high wear resistance and heat dissipation in LHB coaches and locomotives. This critical part integrates with cylinders and levers for uniform force application across axles.

Choosing the right partner for railway manufacturing is critical for reliability, safety, and performance. Vaani Precision Industries delivers high-strength Railway Components—including critical assemblies like the heavy-duty Brake Head and high-tensile Control Arm—using advanced CNC machining and in-house fabrication. By leveraging Precision Engineering and ISO-certified quality systems, our solutions drive performance and durability for India’s rolling stock, traction, and rail infrastructure.

- Zero-defect manufacturing and rigorous quality control.

- Consistent performance for dynamic load and high-stress rail environments.

Precision gears, shafts, and housings manufactured from certified, high-strength alloys.

Designed for maximum resilience and operational longevity.

Scalable manufacturing for prototypes and volume production.

Custom solutions for diverse railway system requirements.

Stage-wise inspections and metrology testing for every production batch.

Certified materials and traceable supply chains to uphold safety standards.

Proven Rail Engineering Expertise: Indian Railways possesses deep-rooted technical expertise gained from decades of designing, manufacturing, and maintaining rolling stock and infrastructure. This expertise is supported by specialized research, rigorous testing, and continuous process improvements to meet the exacting demands of railway operations.

Advanced Metallurgical Capability: The railways employ state-of-the-art metallurgical processes to produce high-strength steels and alloys vital for components such as rails, wheels, and axles. This capability ensures materials exhibit exceptional durability, wear resistance, and safety under heavy loads and variable weather conditions.

Trusted Track Record with Indian Railways: Having contributed extensively to projects across the country, the organization has established a reputation for reliability and quality, maintaining critical infrastructure in diverse and challenging environments. Its long-standing service record with Indian Railways demonstrates consistent on-time deliveries and robust performance.

Safety, Reliability, and On-Time Delivery: Stringent quality management, compliance with safety standards, and adoption of predictive maintenance practices ensure safe and reliable railway operations. The commitment to strict timelines and operational readiness minimizes downtime and enhances passenger and freight service efficiency.