Unlocking Potential: Advanced CNC Machining Powers Strategic Sectors

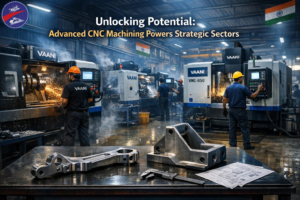

In an era where performance hinges on precision, advanced CNC machining for strategic sectors stands as a cornerstone of modern manufacturing. From railway bogies to defence platforms, automotive drivetrains to farm equipment, every mission-critical system relies on components that are accurate, durable and traceable. Vaani Industries bridges the gap between design intent and field reality by applying sophisticated CNC processes to produce these vital parts.

The company’s facility is equipped with turn-mill centres, high-speed VMCs and grinding machines that handle complex geometries in tough materials. Brake levers, coupler pins, suspension shafts, gear blanks and control brackets emerge from these machines ready for assembly, inspection and deployment. What sets this apart is not just the technology but the disciplined application that ensures consistency across batches.

The engineering behind the machines

CNC technology has evolved far beyond basic turning and milling. Today’s machines support simultaneous multi-axis operations, live tooling and high-pressure coolant that enable single-setup production of intricate features. For precision engineering for railways, this means bogie components with integrated slots, holes and radii that would otherwise require multiple handling steps.

Vaani Industries leverages these capabilities to serve demanding applications. A single part might combine roughing, finishing, drilling, tapping and even thread rolling in one cycle. Program optimisation reduces tool changes and minimises cycle time, allowing faster response to customer needs. Fixture design plays a crucial role here—custom jigs hold irregular shapes securely, protecting tolerances during heavy cuts.

For defence localisation suppliers, the stakes are even higher. Components must meet not only dimensional specs but also material integrity and documentation standards. The company’s process planning includes validated tool paths, probe cycles for in-cycle checks and automated documentation that supports audits.

Materials that perform under pressure

Strategic applications expose parts to extreme conditions. Railway couplers endure millions of cycles under shock loads. Defence brackets resist vibration and corrosion. Automotive shafts handle torque and heat. Agricultural linkages fight mud and wear.

Advanced CNC machining starts with material selection. Vaani Industries works with alloy steels, stainless grades, case-hardening steels and aluminium for specific needs. Post-machining treatments like nitriding, phosphating or stress relieving are coordinated with approved vendors. Grinding follows where surface finish or roundness is critical, ensuring that bearings, seals and mating surfaces perform as intended.

Quality as a process, not an afterthought

Quality machined components begin with stable processes. The company uses statistical process control to monitor key dimensions, tool wear and cycle variations. First-article inspections lock in the baseline, and subsequent lots are checked against master samples. CMM reports, gauge calibrations and material certificates form a complete traceability chain.

This rigor pays off in customer confidence. Railway authorities and OEMs can rely on parts that meet RDSO specs or equivalent standards. For automotive and agricultural parts manufacturing, the consistency supports just-in-time delivery and lean assembly lines.

From prototype to production scale

New programmes often start small but grow quickly. Vaani Industries supports the full lifecycle. Prototypes are machined from customer 3D models, with rapid iterations based on feedback. Trial runs validate process capability, and once approved, production ramps up with dedicated tooling and work instructions.

Cross-training across machines builds flexibility. Operators certified on multiple centres can shift between railway brake parts and defence housings as volumes change. Planning teams forecast material needs and manage vendor schedules to avoid delays.

Partnering with industry leaders

Collaboration defines success in strategic manufacturing. Vaani Industries engages early with design teams to discuss manufacturability. Can a profile be simplified without losing strength? Is a tighter tolerance needed, or can it be relaxed for cost? These conversations lead to better designs and smoother production.

Customer audits and vendor rating systems keep standards high. Feedback from field performance informs process tweaks, creating a cycle of continuous improvement.

Future-ready investments

The pace of change in railways, defence and mobility demands constant evolution. Recent upgrades include longer-travel VMCs for larger housings, improved spindles for harder materials and digital nesting software that maximises raw-stock utilisation. Operator training on newer controls and safety protocols ensures smooth adoption.

Sustainability also shapes decisions. Energy-efficient machines, coolant recycling and scrap minimisation align with broader industry goals while keeping costs competitive.

The human element

Behind every advanced CNC program is a skilled team. Programmers who optimise paths, operators who spot anomalies, inspectors who verify results and engineers who tie it all together. Vaani Industries invests in their growth through hands-on training, certifications and exposure to diverse projects. This builds a workforce capable of handling tomorrow’s challenges today.

Impact beyond the shop floor

Advanced CNC machining for strategic sectors does more than produce parts. It supports localisation goals, reduces import dependence and builds industrial capacity. Reliable braking saves lives on rails. Durable linkages boost farm productivity. Strong brackets protect personnel in defence. Each component contributes to systems that serve millions.

Vaani Industries remains committed to this role. By focusing on process excellence, customer partnership and continuous upgrade, the company ensures that its capabilities match the ambitions of the sectors it serves. For OEMs seeking a dependable source of quality machined components, the door is always open for discussion.

Contact us for more details.